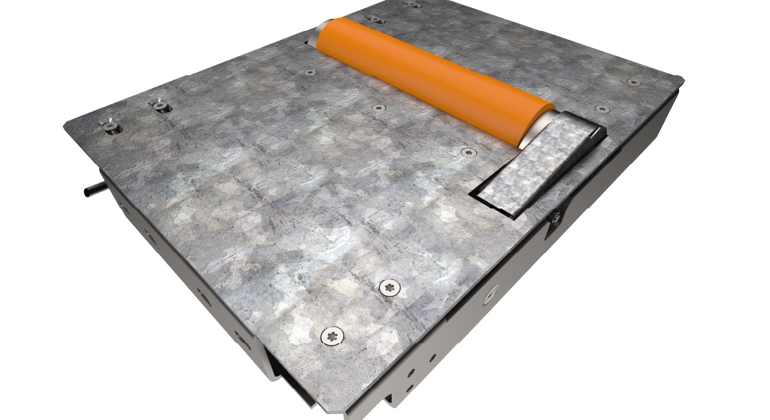

Powered cargo rollers provide a seamless and controlled movement of air cargo, eliminating the need for manual pushing or relying on gravity.

Loading and unloading AKEs and air cargo pallets in and out of trucks - why not do it with a button? The system comprises rise and fall DC 24V rollers combined with a pneumatic rollertack. It handles all flat-bottomed ULD containers and transportation pallets up to 20,000 kgs with no product damage.

This feature ensures safe and efficient loading and unloading processes in diverse environments. Whether it’s loading heavy cargo onto trucks, transferring goods in distribution centres, or handling oversized items at airports.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW