We stand behind the quality and performance of our products and installations. As a testament to our confidence, we offer a 12-month warranty on all our products and installations. This warranty provides our clients with peace of mind, knowing that we are committed to their satisfaction and the long-term reliability of our loading systems.

With this warranty, our clients are assured that their investment is protected, and any manufacturing defects or issues that may arise within the warranty period will be promptly addressed at no additional cost. The warranty demonstrates our confidence in the durability and performance of our loading systems, emphasising our commitment to customer satisfaction.

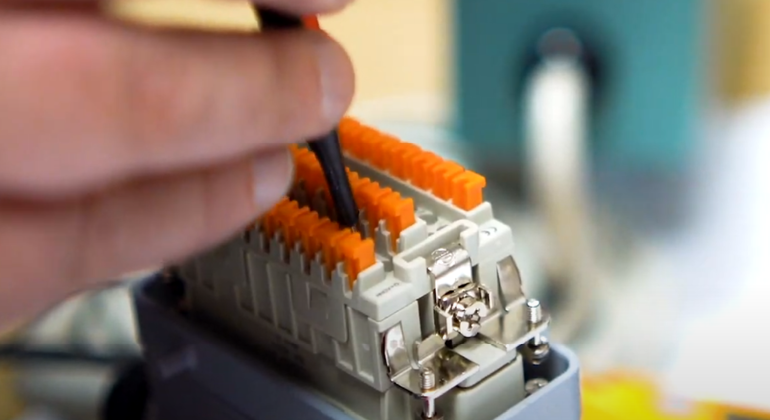

Furthermore, our more than 60 years of industry experience is a powerful indicator of our expertise and stability. Over the decades, we have honed our craftsmanship, engineering capabilities, and customer service to become a trusted leader in the loading solutions market. Our long-standing presence showcases our ability to adapt to changing industry demands and consistently deliver innovative and reliable loading systems.

Choosing Joloda Hydraroll as your go-to loading system partner reduces the risk you’ll benefit from the assurance of a reputable and established company with a proven track record. Our extensive knowledge and experience enable us to understand and cater to our client's unique needs, providing them with tailored solutions that enhance efficiency, safety, and productivity. By partnering with us, businesses can be confident in their choice and build a strong, long-term relationship with a trusted and reliable loading system provider.