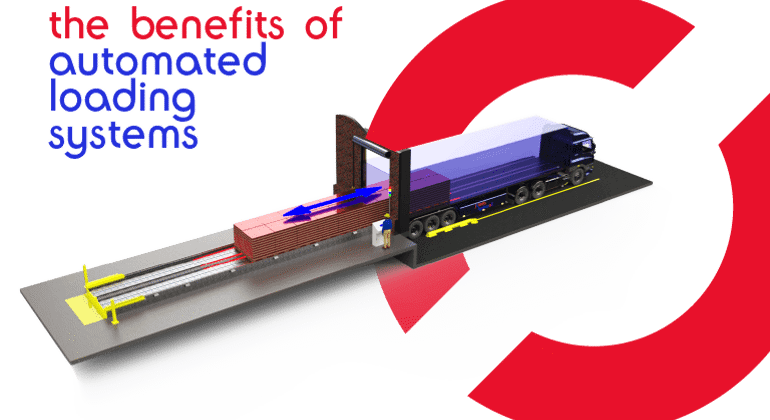

what are moving floor conveyor solutions?

Moving goods from factories to warehouses? Make loading and unloading safe, easy, and fast with our Moving Floor conveyor solutions.

Designed for shifting any palletised, non-palletised, or crate-based goods, the Moving Floor is a heavy duty, flexible slat conveyor belt system.

Connect it directly to your production line conveyors, or use forklifts and AGVs to place your cargo onto the belt.

Whatever your setup, Joloda Hydraroll’s global experience will deliver a perfectly integrated modular design for your trailer or building.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW