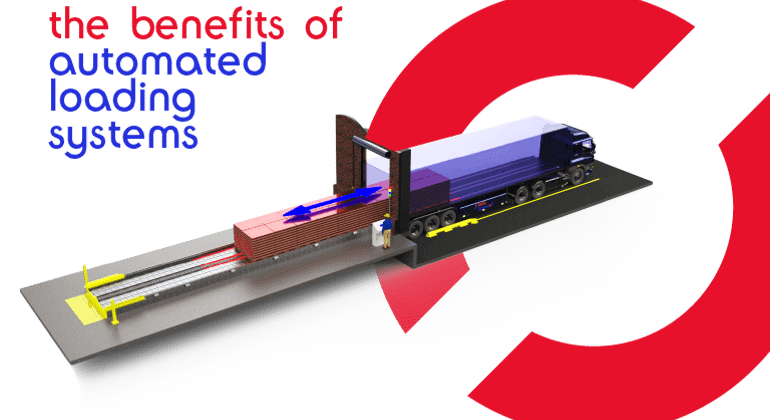

Automated loading systems have become highly useful in the world of logistics and are a way of helping factories, warehouses and other operators to load and unload trailers and containers much quicker. Businesses use them as a tool to improve their efficiency, cutting loading times considerably, and conduct loading and unloading more safely when goods arrive at the loading docks or when the business is dispatching them.

In this guide, we’ll take a look at what automated loading systems are and how businesses can benefit from them. We’ll also take a look at loading methods, plus a deeper look at how Joloda approaches automation and how the company’s systems can make a difference to your loading processes.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW