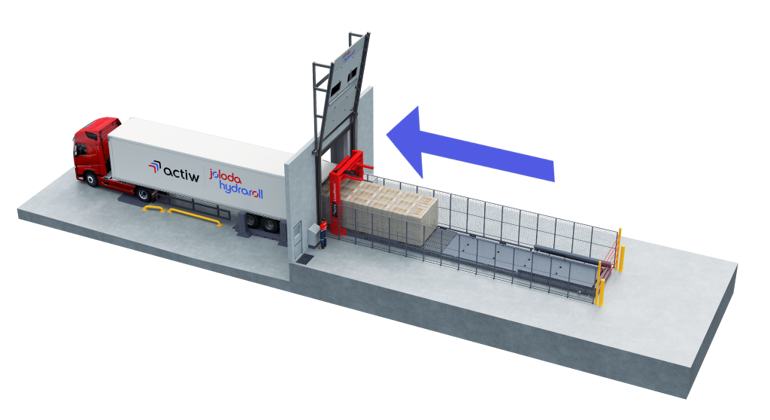

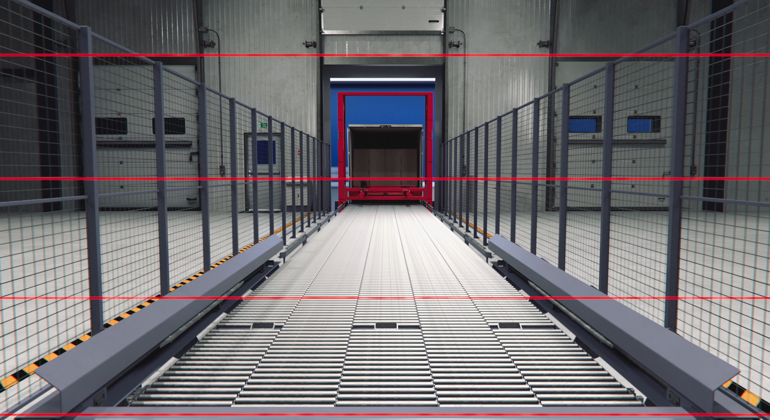

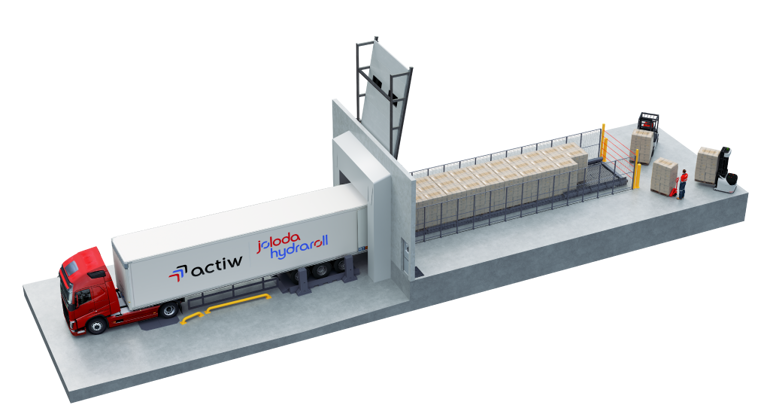

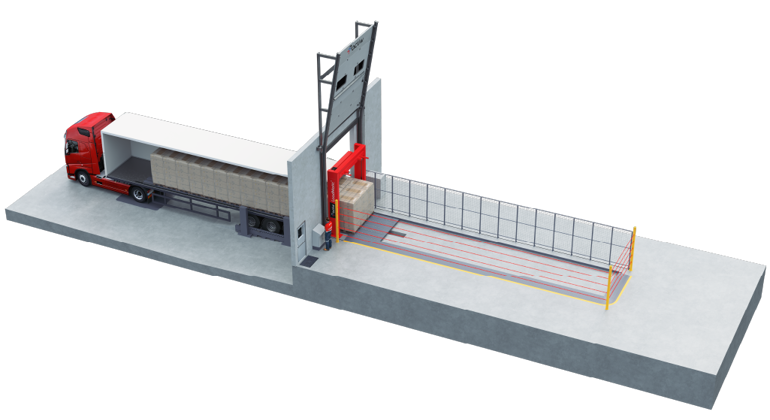

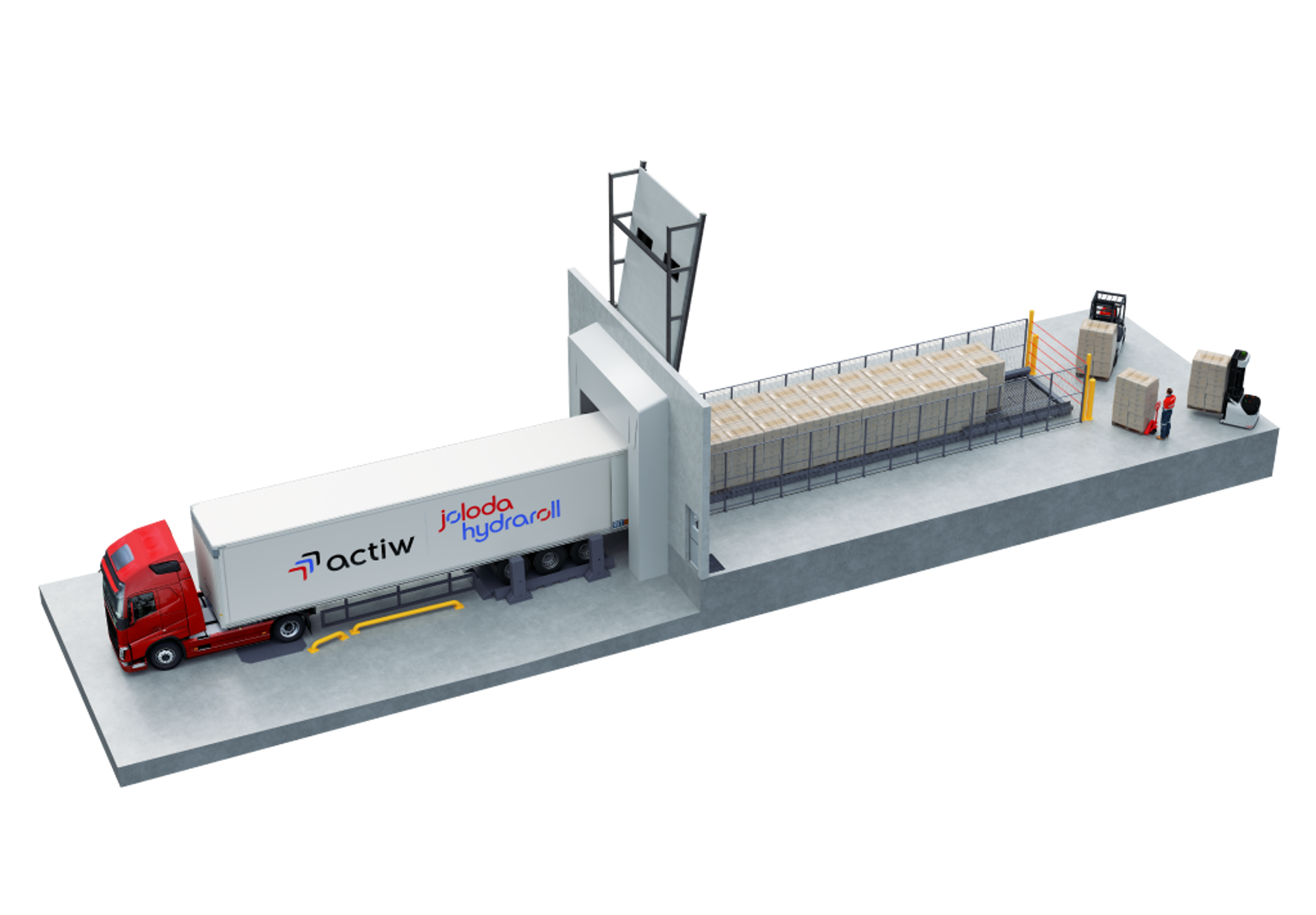

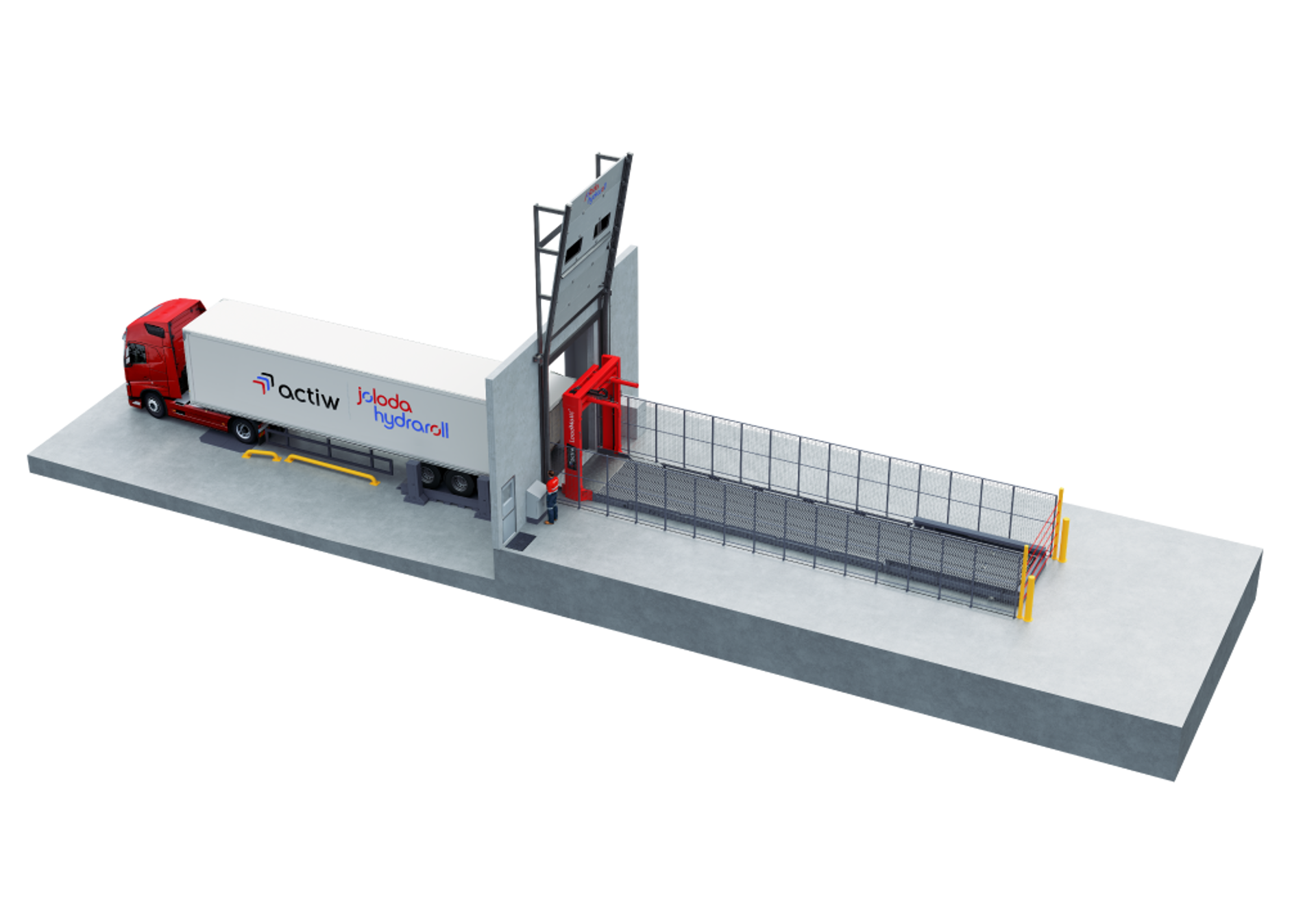

introducing LoadMatic Lite...

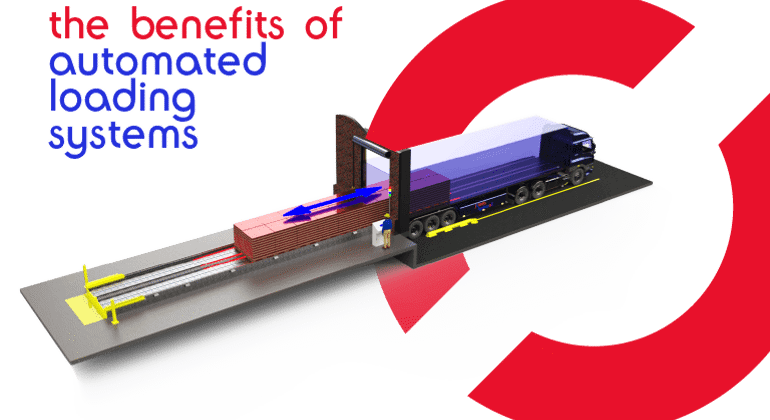

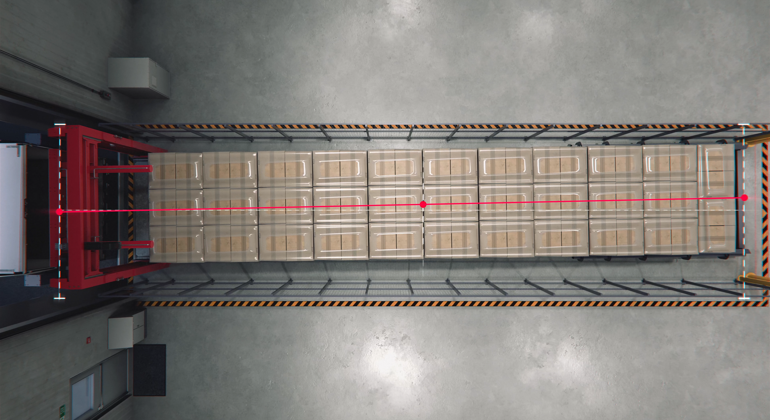

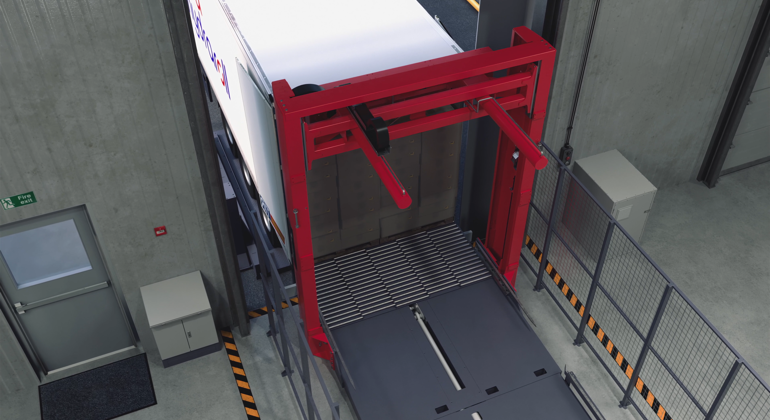

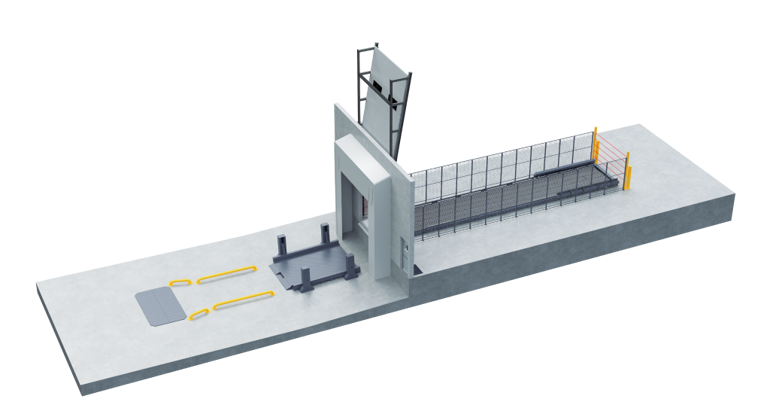

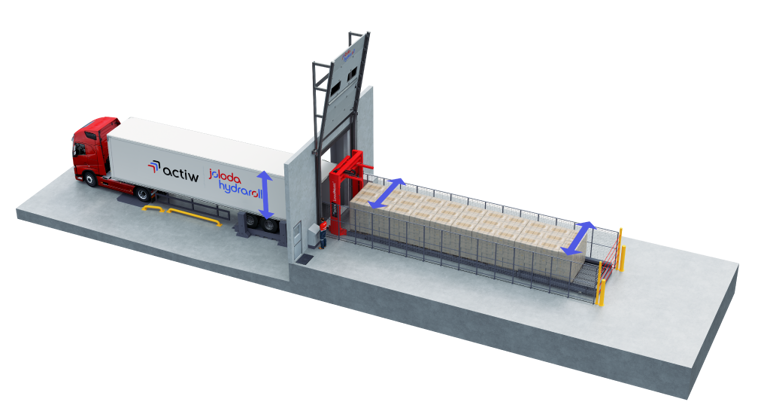

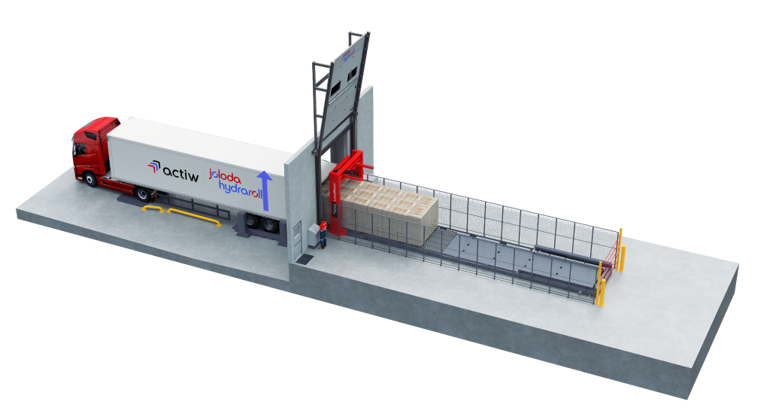

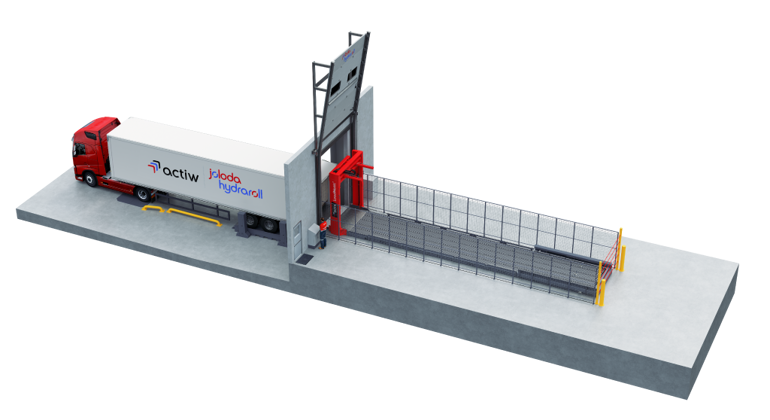

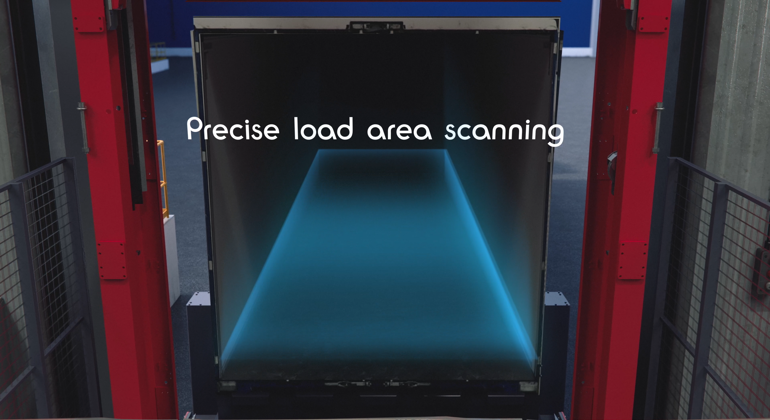

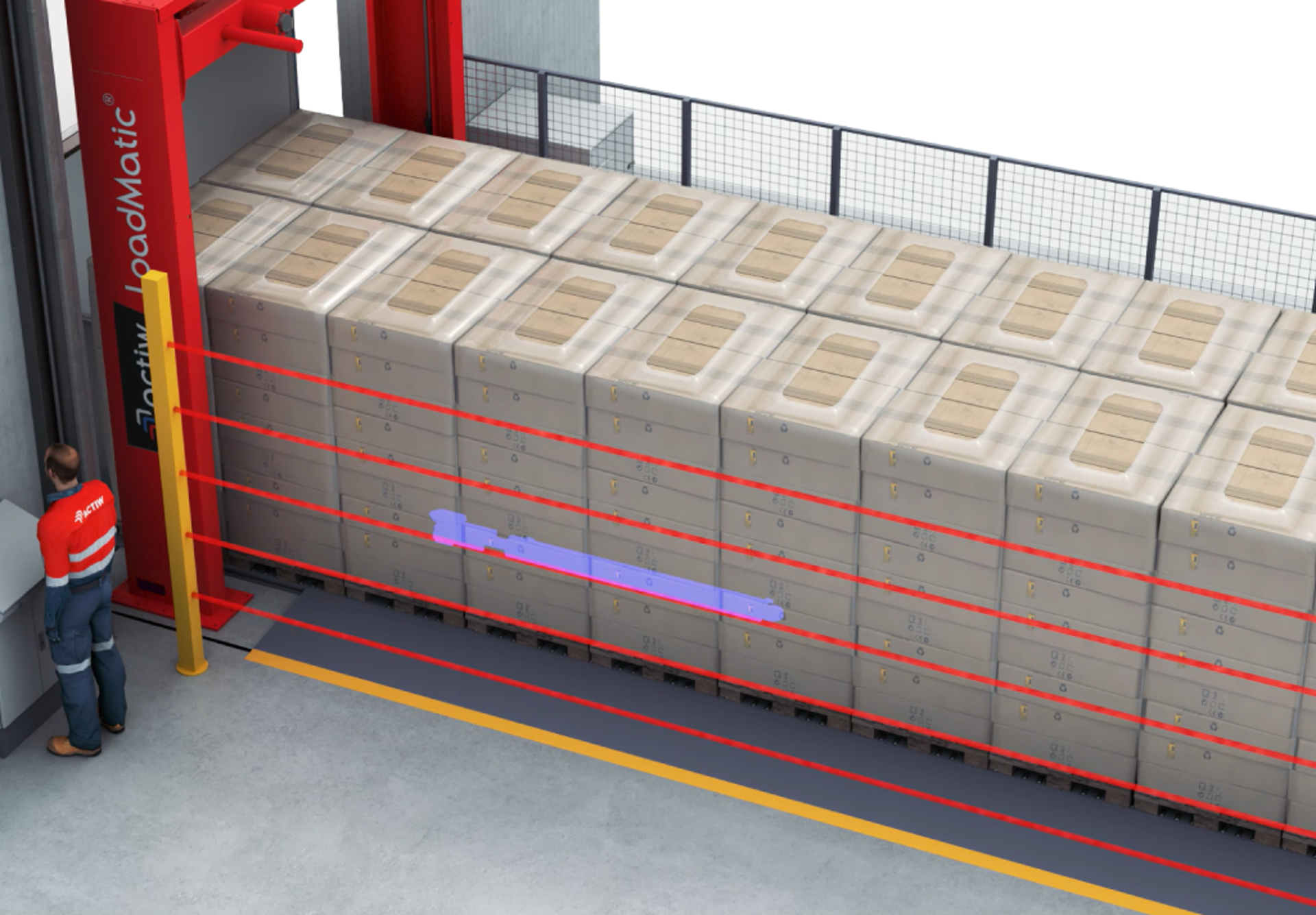

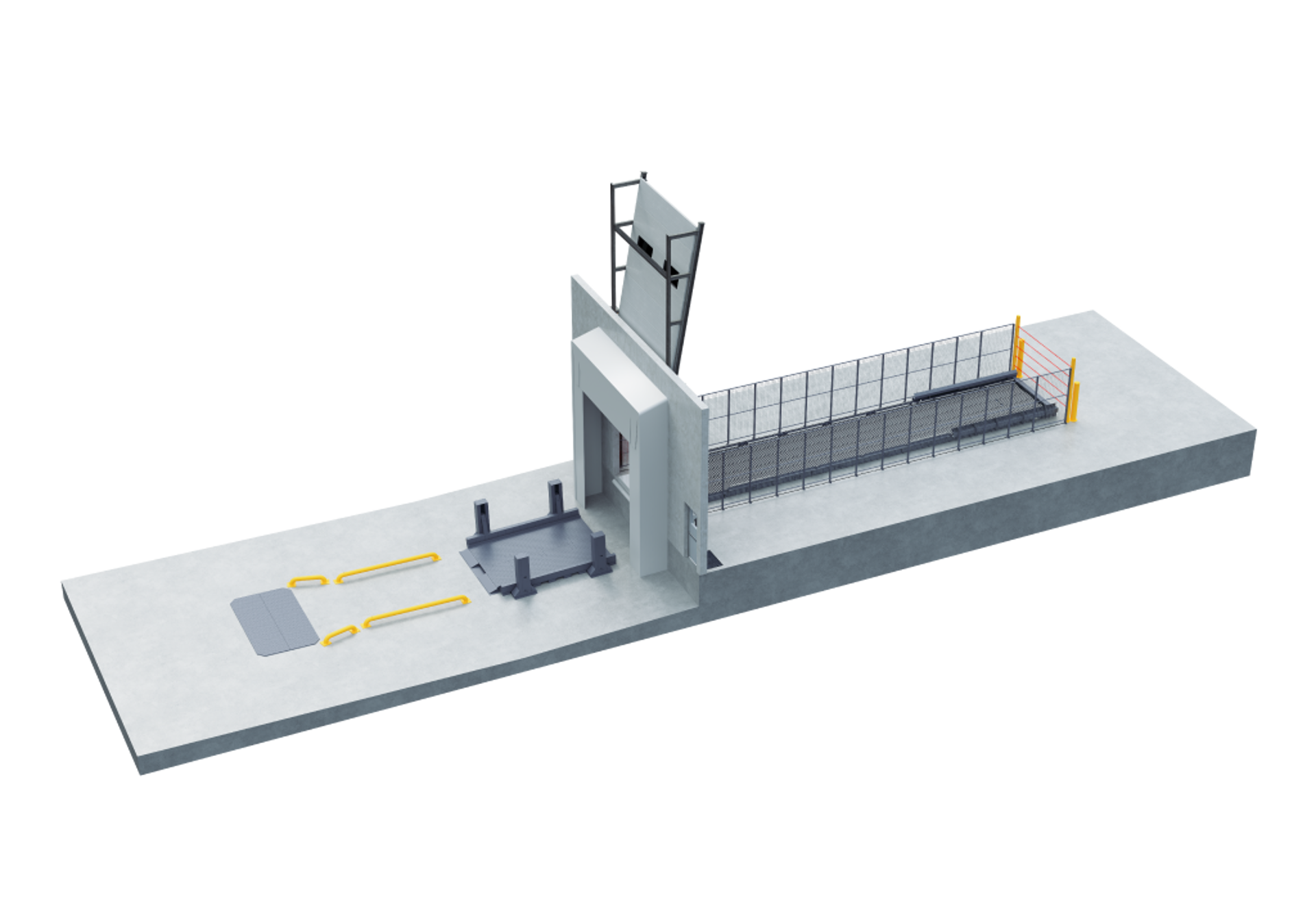

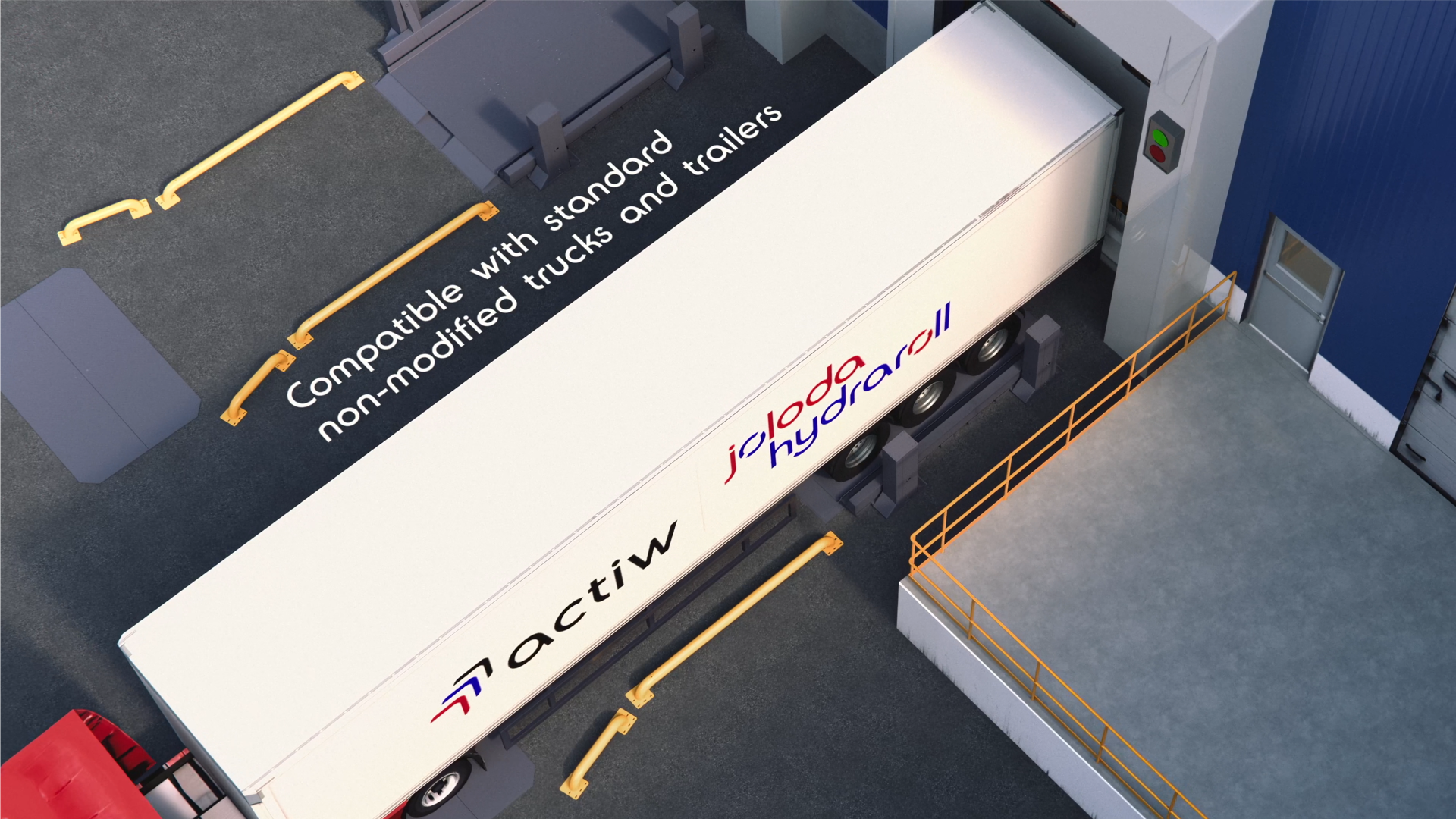

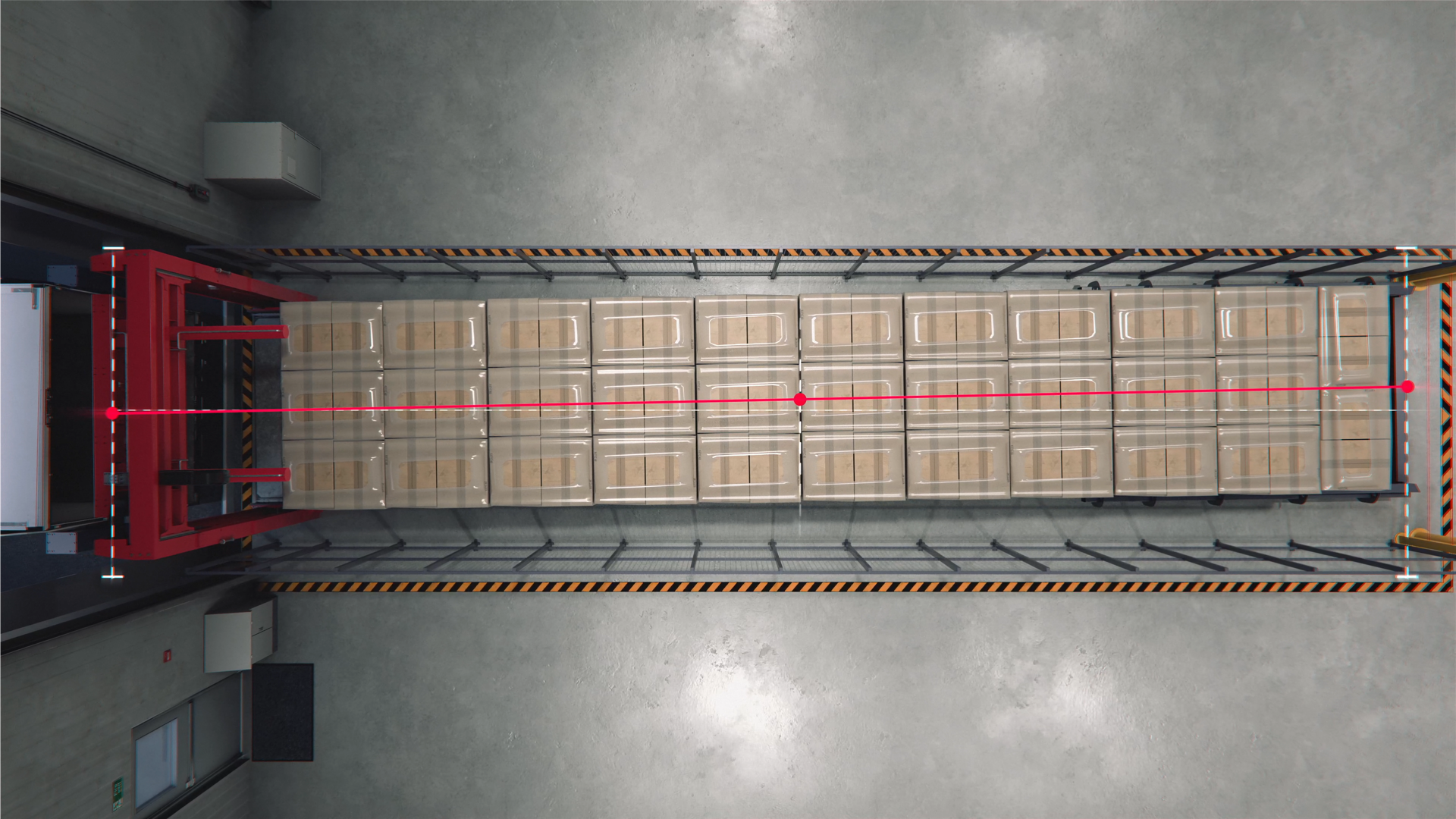

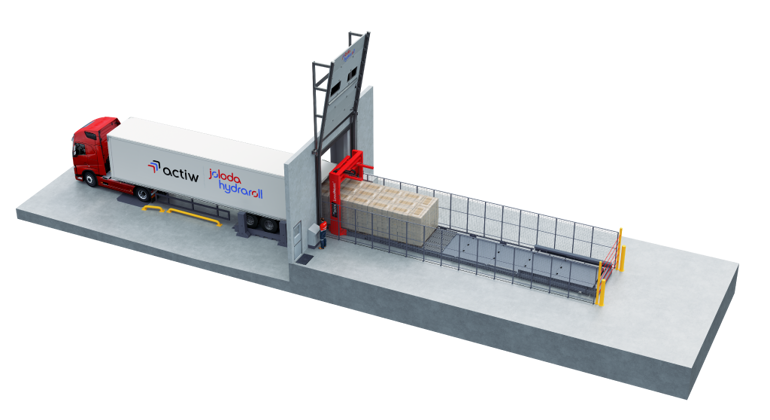

The only automated system that can automate loading for standard, non-modified trucks and trailers with a low upfront cost.

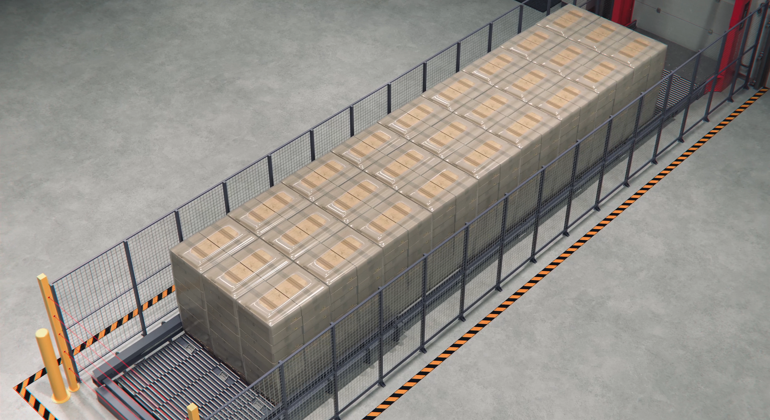

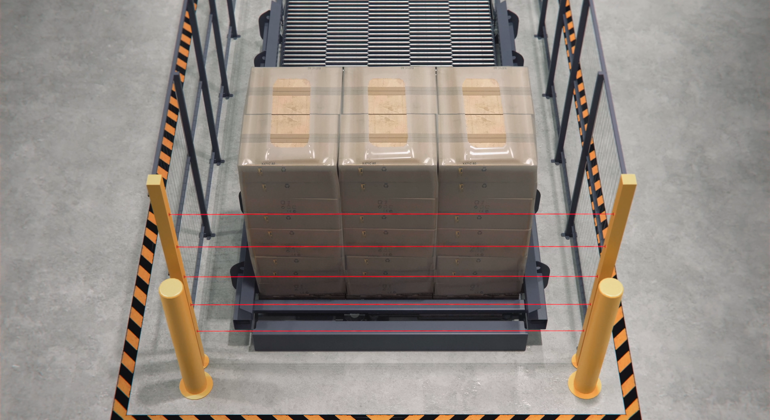

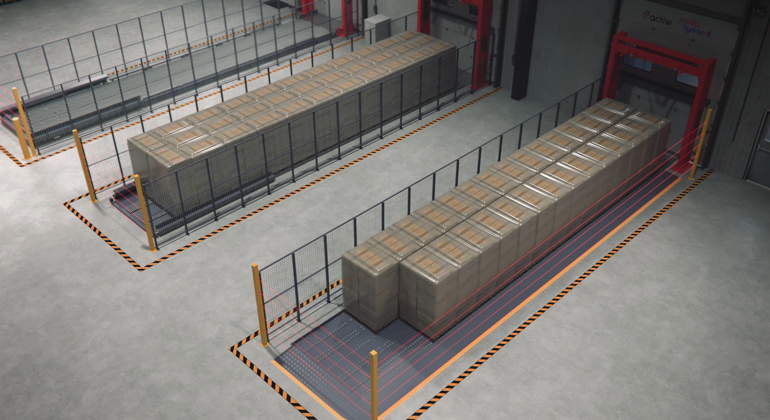

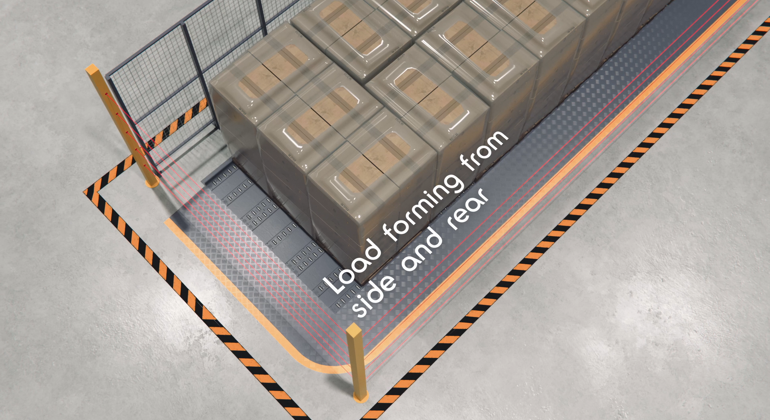

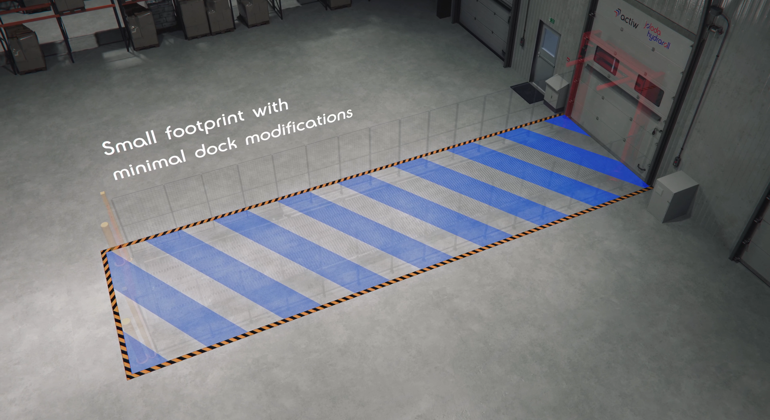

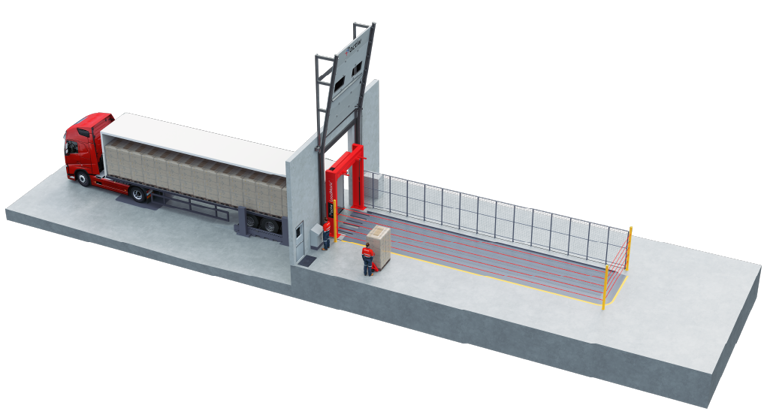

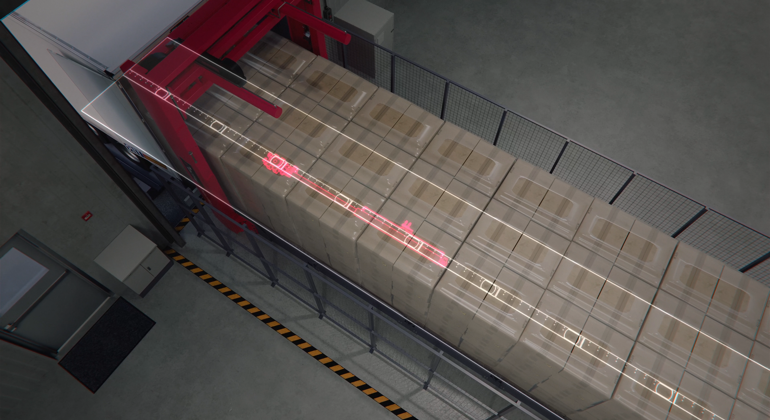

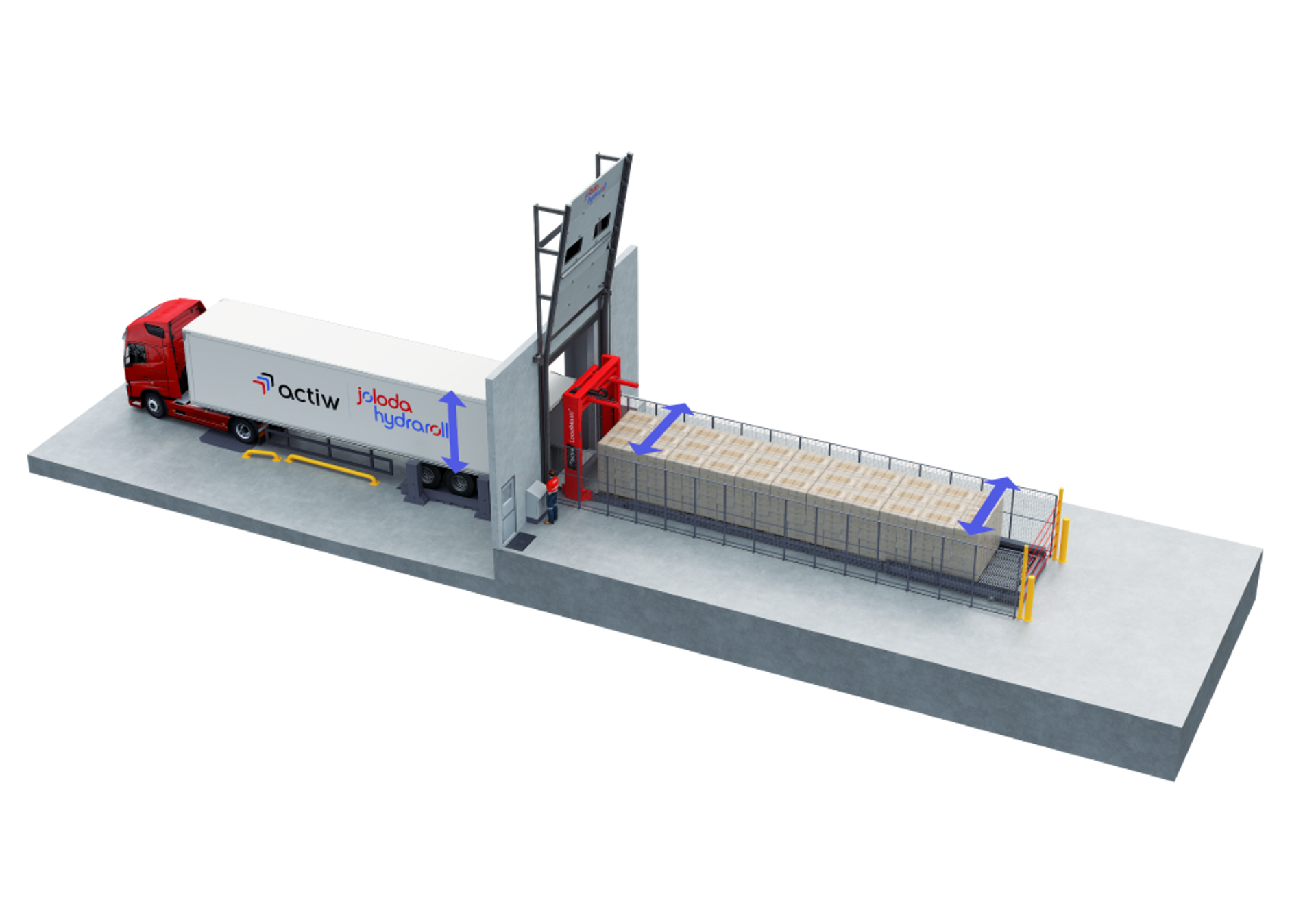

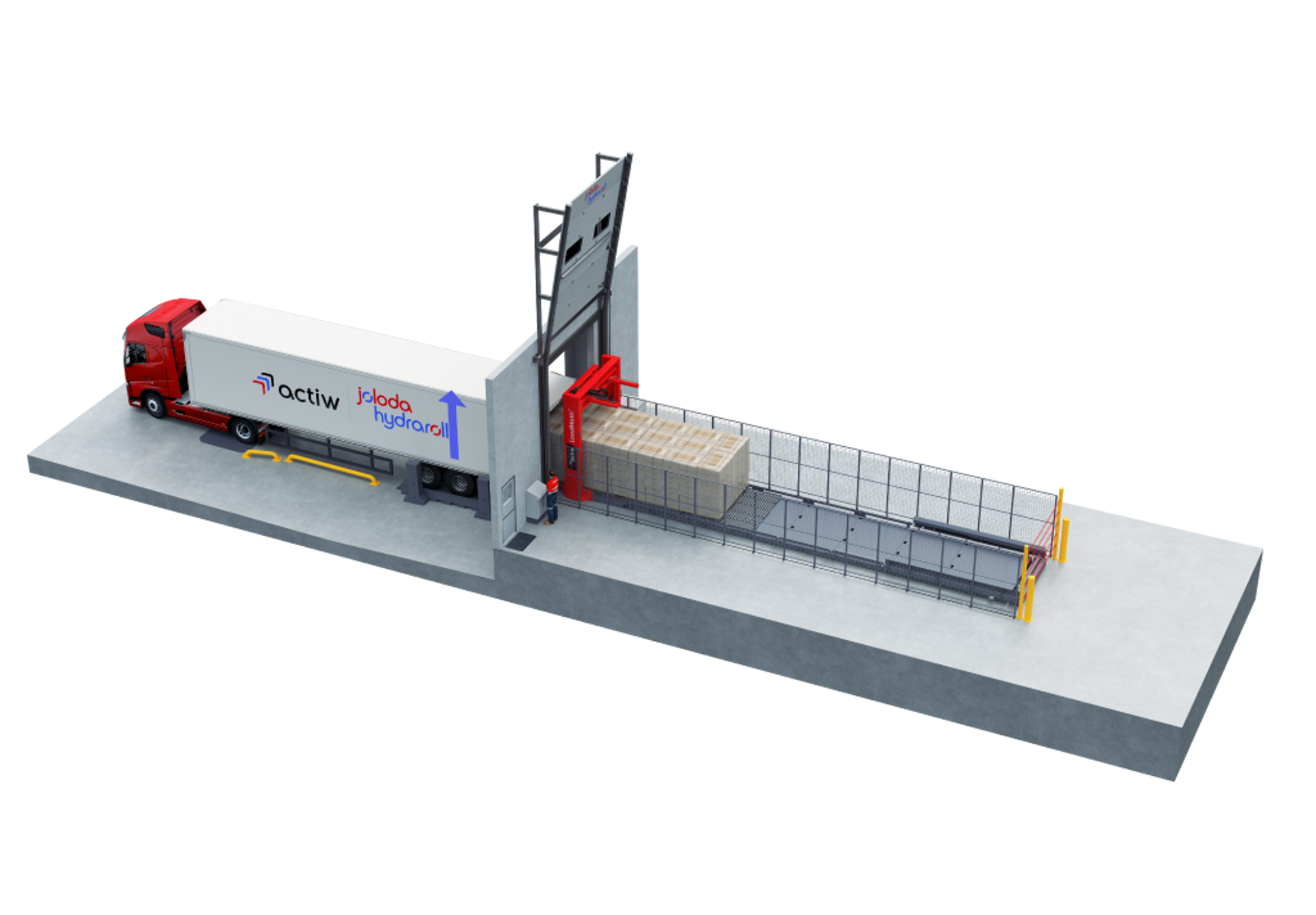

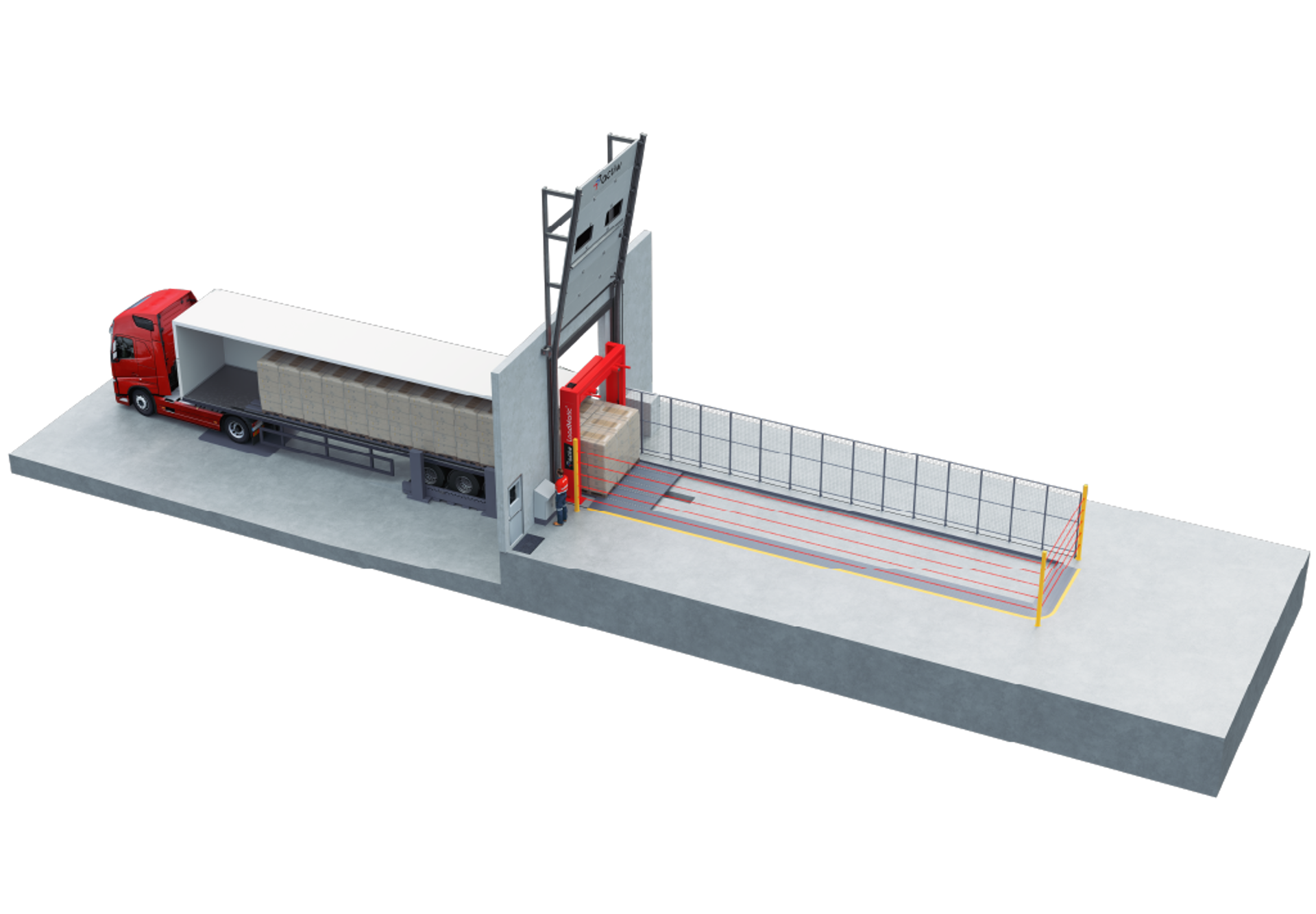

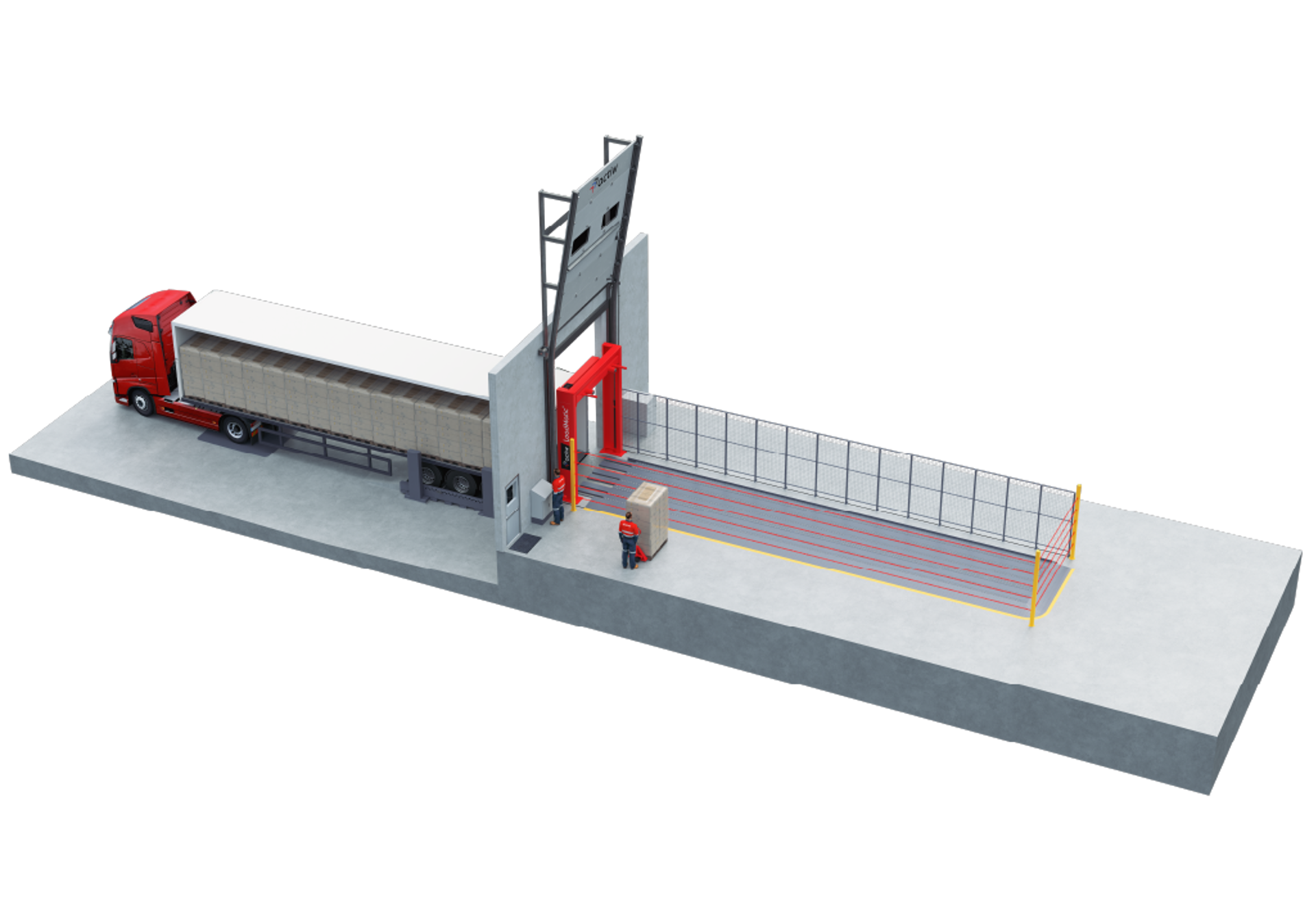

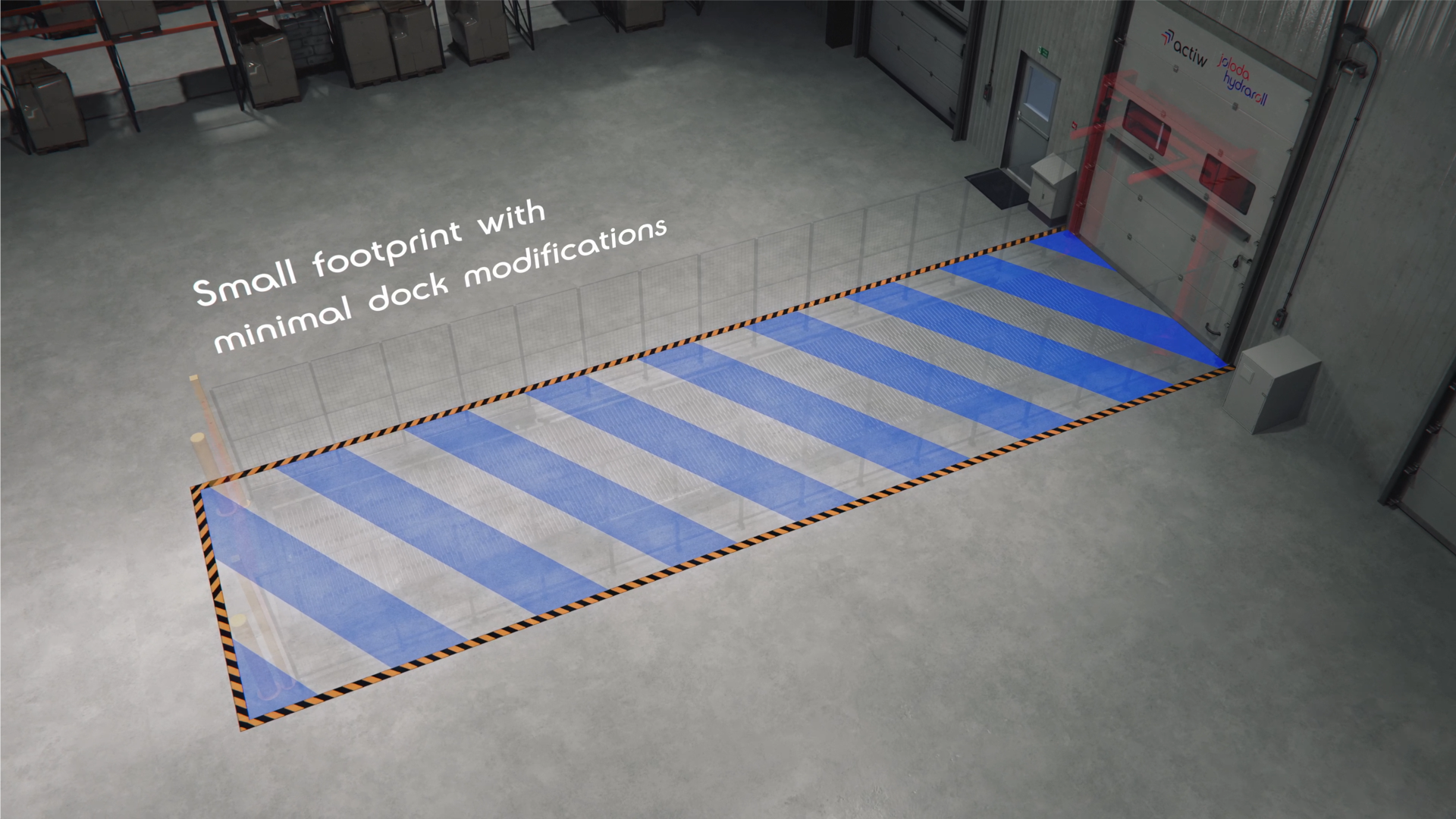

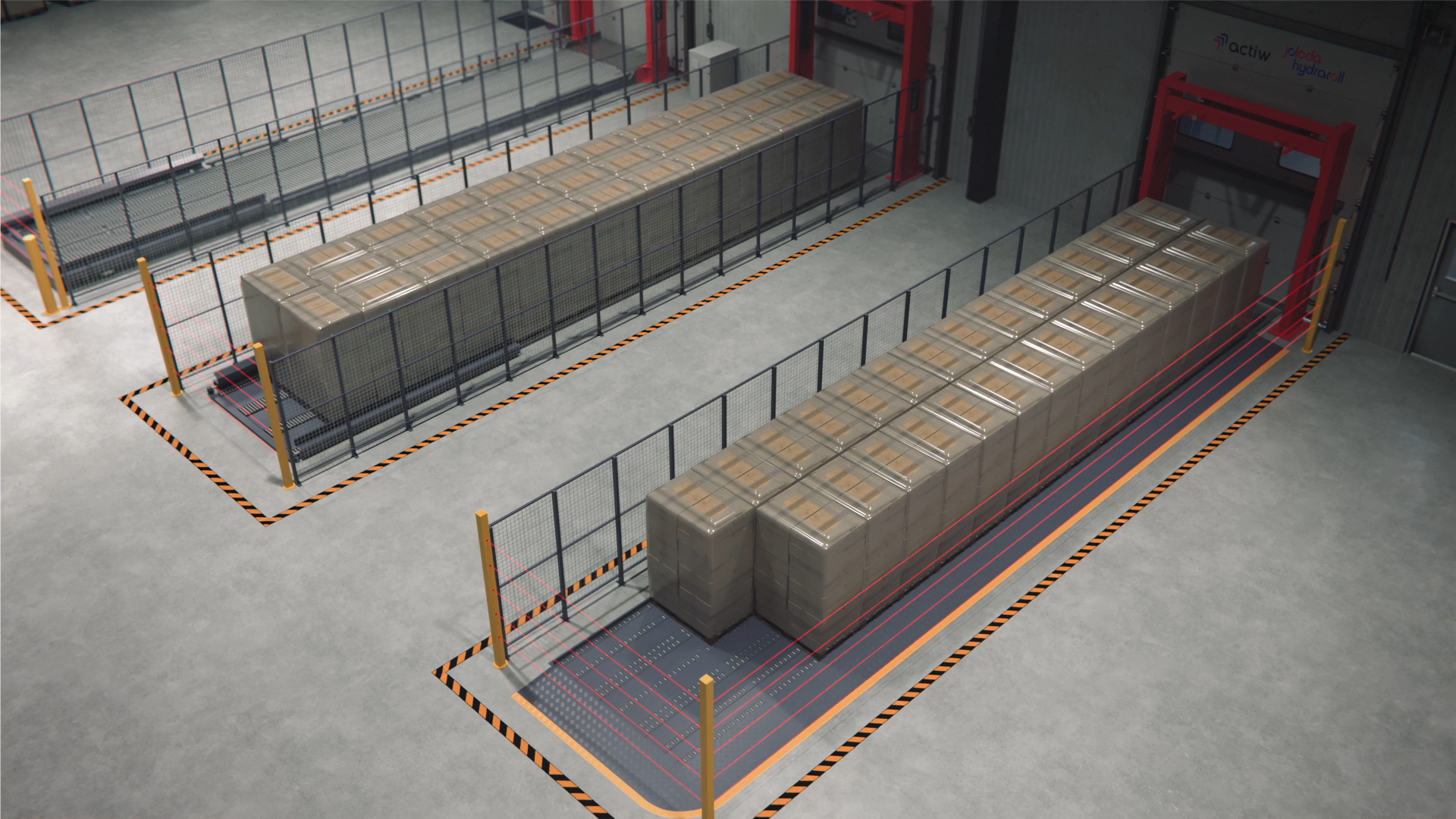

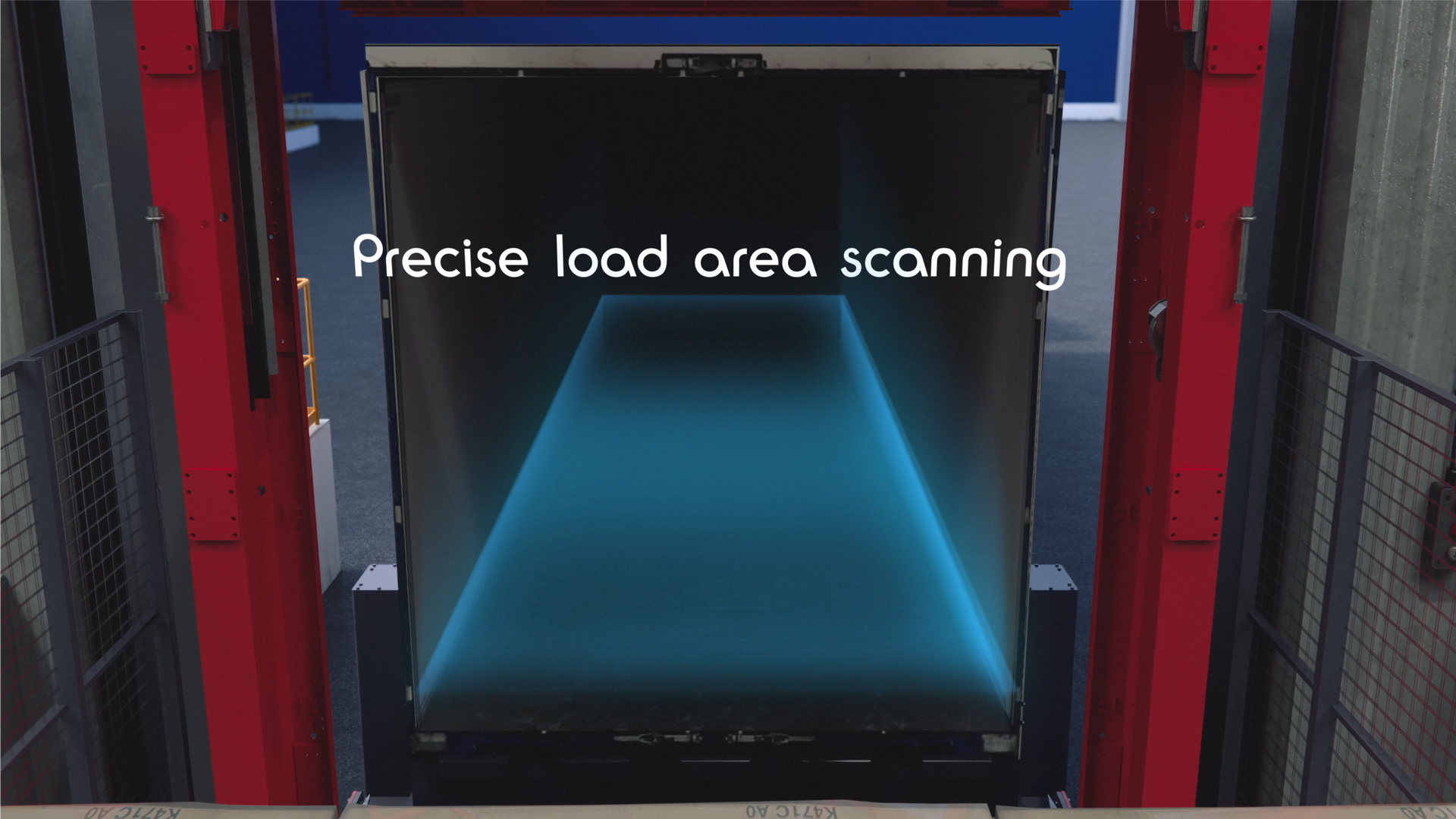

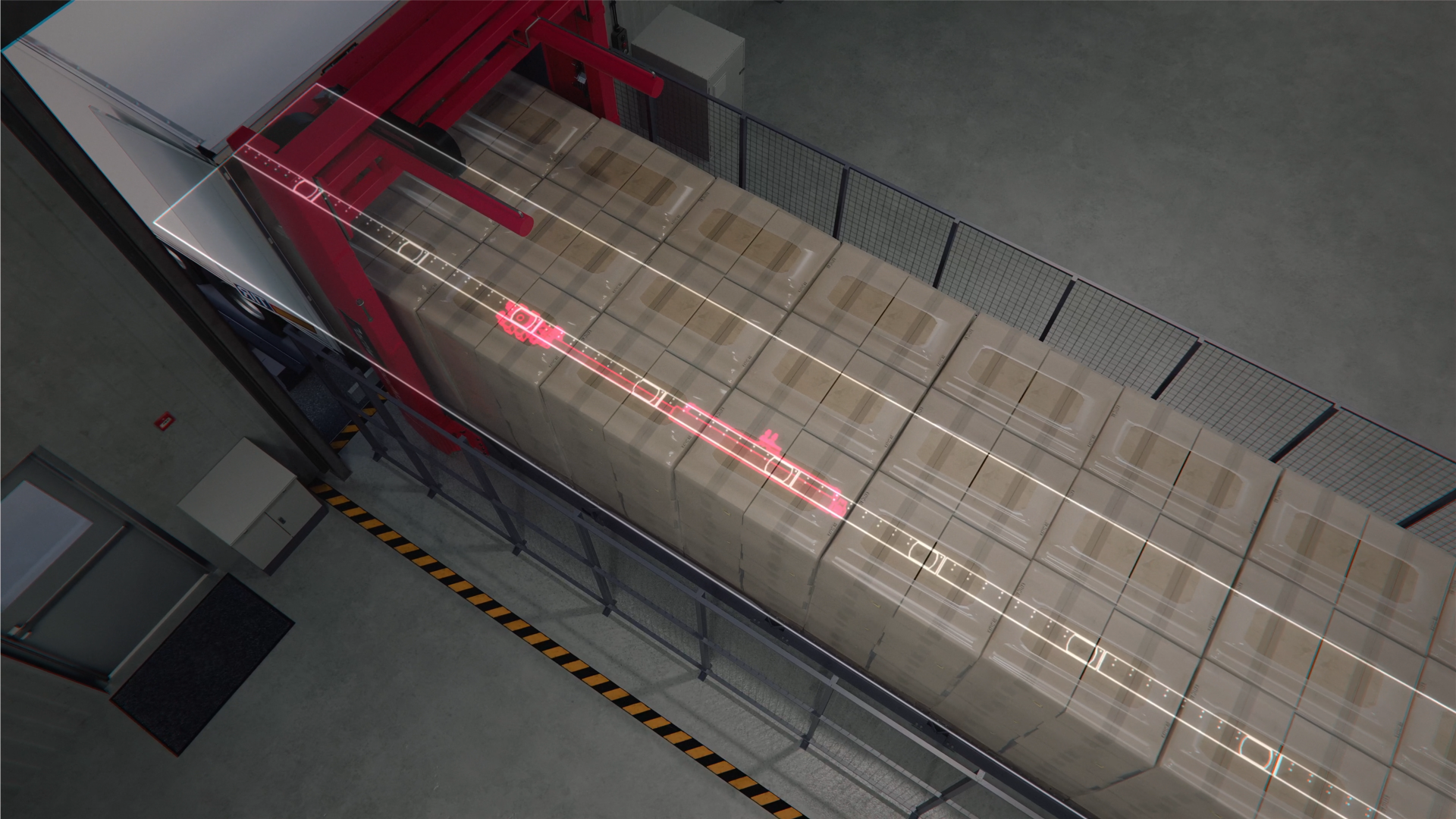

LoadMatic Lite is a versatile, entry-level Automated Truck Loading System, ideal for manufacturers and distribution centres looking to increase their daily load volume beyond what’s achievable with manual forklift operations - all without major site changes or fleet modifications.

These businesses often deliver loads directly to warehouses or shops where forklifts are used for manual unloading. It is specifically designed to help meet higher throughput demands by improving the speed and efficiency of the loading process within manufacturing plants or main distribution centres.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW