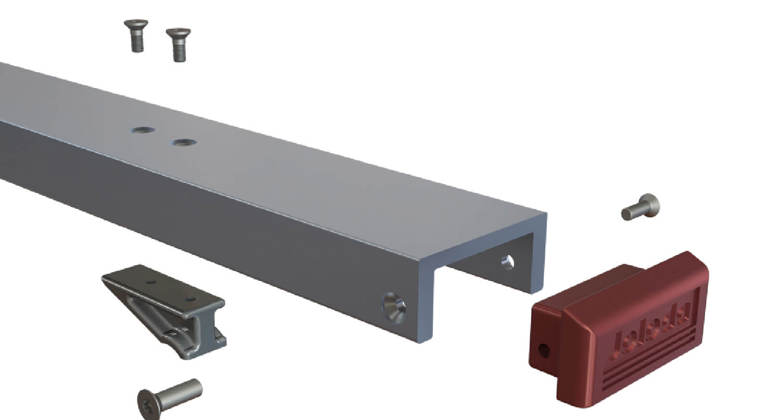

Joloda Hydraroll has recently added a new product to the Skate & Track loading system lineup, we now also offer a lightweight aluminium skate to complement our original steel-type skates. The aluminium skate is half the weight (with a lifting capacity of 1,600kg per pair), which makes it even easier to handle – the ideal solution when weight-saving is key.

Our new aluminium skate weighs only 7kg each and is 5kg lighter than our typical steel skate-type, making it an undeniably lightweight system. This reduces the strain on the operator when manually manoeuvring the skate (and the load) on and off trucks.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW