Sverdrup Steel is a global supplier of stainless steel and nickel-based alloys with over 30 years of expertise in materials technology. Known for quick delivery and high-quality standards, the company serves industries such as oil and gas, manufacturing, and renewable energy.

Their Stavanger headquarters houses the largest stock and service centre, specialising in high-performance materials compliant with stringent standards like NORSOK and IOGP. With certifications including ISO 9001, ISO 14001, and ISO 45001, Sverdrup Steel is a leader in quality and operational excellence.

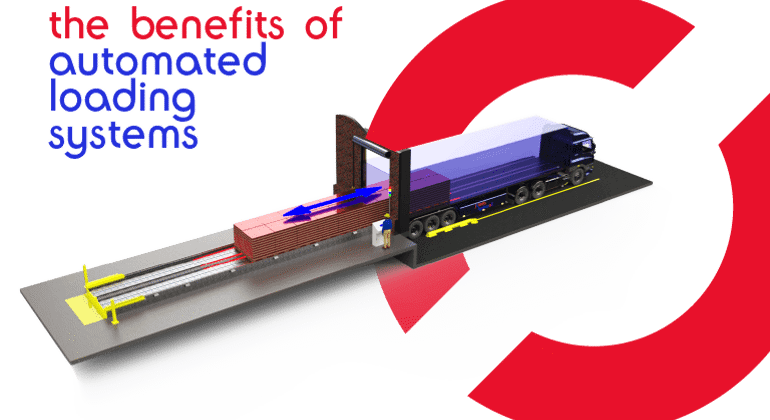

In early 2024, the company announced its new 13,000 sqm service centre in Hedensted, Denmark, which will be fully operational by January 2025. Strategically located near Europe, Scandinavia, and the UK, the facility will streamline logistics, enhance alloy processing, and demonstrate Sverdrup Steel’s commitment to innovation, sustainability, and exceptional service.