McPhersons are specialists in what they do. Moving large quantities of spirits around the UK, they require a loading system that offers them efficiency and flexibility and, above all, safety.

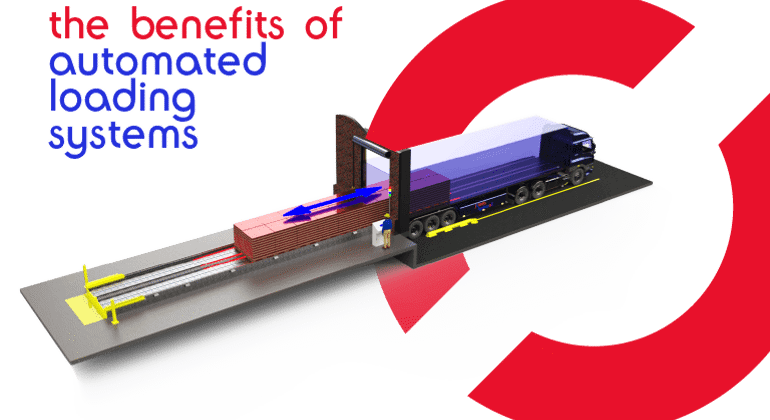

Moving large quantities of flammable liquid by road requires a solution that is safe, both in transport and during loading and unloading. When on the truck, the load needs to be fully secured and locked into place, so that it doesn’t move around in transit. Loading and unloading needs to be done in a controlled way, again to ensure safety, and the entire solution needs to be flexible so that it works with the systems in place at the many locations they deliver to.

The product is highly flammable so safety is of utmost importance therefore conforming to Atex regulations is a must for all equipment used in this industry which stands for Atmospheres Explosible. Our systems are all Atex compliant as we have a certified engineer responsible for the design, risks, documentation and components used in the system to ensure its explosion proof.