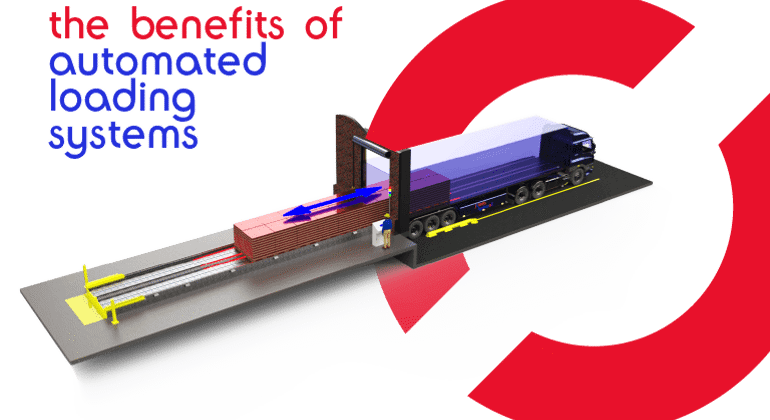

Joloda Hydraroll has been busy helping the leading tyre and wheel assembly partner for the automotive industry in Europe, Eurofit increase the efficiency of their operations through the implementation of our Automated Loading Solutions.

In this case study you will learn how our Automated Loading technology has been utilised by the Automotive Sector to streamline their operations and become safer.

Book a FREE Loading Assessment

Learn how to make the loading process safer and more efficient with a no-obligation assessment...

BOOK NOW